In a report published by McKinsey & Company, the term “Industry 4.0” didn’t exist in Google searches until 2014 but the new survey revealed that 68% of respondents have considered “Industry 4.0” as a strategic priority and 70% of companies have started deploying new technologies.

The world has witnessed tremendous technological advancements in the past decades that have immensely affected the way businesses operate and have helped not only the companies but also the nation to prosper economically. The macro and micro-economic impact caused by the development of technology is magnificent and it has been predicted by experts that the world is yet to witness the miracle of advanced technologies. As we have already witnessed the first, second, and third industrial revolutions, the world is heading progressively towards the fourth industrial revolution. As per the World Economic Forum:-

“The fourth industrial revolution (Industry 4.0) is a new chapter in human development, enabled by extraordinary technology advances commensurate with those of the first, second, and third industrial revolutions.”

Technologies of Industry 4.0

“Industry 4.0” or “IR 4.0” may seem vague and ambiguous to most people and it could be a case where most non-technical people/managers/CEOs are puzzled about what they mean, what kind of technology would be part of it and what sort of changes could they witness within the next decade. As per the same article, IR 4.0 would involve 4 distinctive technologies:-

- Connectivity, data, and computational power: Cloud technology, the Internet, Blockchain, Sensors

- Analytics and intelligence: Advanced analytics, Machine learning, Artificial intelligence

- Human-machine interaction: Virtual reality (VR) and Augmented reality (AR), Robotics and automation, autonomous guided vehicles

- Advanced engineering: Additive manufacturing (such as, 3-D printing), renewable energy, nanoparticles

Advantages of Industry 4.0

We have seen greater utilization of technologies such as cloud computing, Blockchain, AI, VR/AR, and 3D printing and there is no doubt how these technologies bring immense value to any business and mostly to mankind. According to IBM, technology is an integral part of any business and has profoundly helped in business transformation. With the aid of transformative technologies that are available in the Industry 4.0 era, businesses can significantly increase value by changing their operations and business models. To anticipate and respond to disturbances, shifting customer wants, and fresh market opportunities, technologies help businesses coordinate decision-making, operations, and data.

In one report published by the World Economic Forum, they performed an econometric analysis of the productivity impact of new technologies present in the IR 4.0 era, with over 16,000 companies across 14 industries, they found two major results:-

- Companies experienced increased revenue and productivity growth.

- Companies became more efficient in their operations, enhanced customer experiences, and discovered new business models.

Roadblocks to Industry 4.0

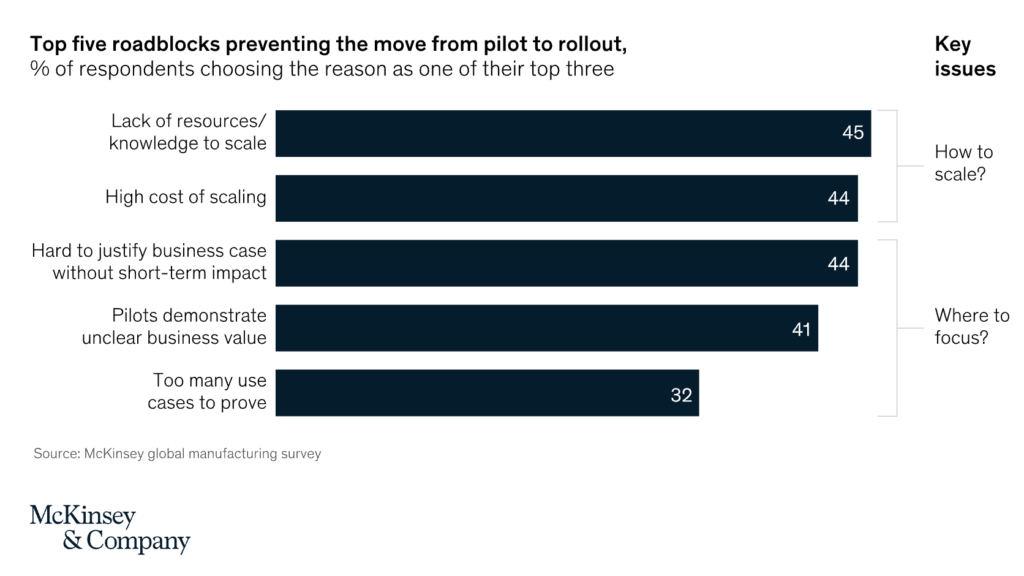

Despite all the positive ROI of “IR 4.0”, there are still major roadblocks to implement and execute it. The below diagram is adapted from the survey done by McKinsey & Company, which illustrates major hurdles in trying to implement smart technologies that are available in “IR 4.0”

The Solution to the Roadblocks

As presented in the diagram, the major roadblocks to achieving the full potential of industrial 4.0 are a lack of resources and appropriate knowledge, increased costs, businesses and managers’ skepticism towards IR 4.0 technology, and unclear business values with vague business models. That being said, a question might strike on everyone’s mind; “Is it so that there is no solution where we could not fully reap the benefits of IR 4.0?” The question can be answered with a famous saying, that quotes;

“If there is a problem, there is a solution. If there is no solution, there is no problem”

Henrik Von Scheel is a famous strategic thinker on growth and innovation. He describes “the three key drivers for Industry 4.0 success: think value, not tech; think people, not tools; and set clear targets from the start.” These suggestions pose great insights on how can we fully maximize the value of the technologies of Industry 4.0.

First and foremost, technology is just a tool. The value generation or positive impact is what matters the most. Therefore, before thinking of tech, carefully analyze what value you would like to see it producing and whether the value is really a “real value”? Questions such as, Would it help to increase our operational efficiency, Would it help to reduce cost and maximize profits, Would it help to scale our business sustainably, Would it help to create new business opportunities/models might help assess if the technology is fit for you or not. Secondly, investing in your people and having a strategic approach to talent management is highly critical. The engineering team and business team must be well-nurtured and companies should create an innovative environment where the “it is okay to fail” principle is followed. Innovation takes time and it is only achieved through small and continuous change. The third important principle to bear in mind is to set clear and achievable targets. Most of the technologies in IR 4.0 have many use cases but coming up with a strong business model is very difficult. There are also serious concerns about the ethical use of these tools. Therefore, companies need to set realistic goals and roadmaps on how are they going to implement/develop/commercialize these technologies.

WeAre Here to Help

Our company, WeAre, is at the forefront of the technology landscape and we understand the importance of adopting technology to achieve organisational excellence. With years of experience and a highly competent team comprised of developers, cloud engineers, and security consultants, we have worked with a wide range of technologies and assisted our clients in realising their maximum potential. Our consultants are dedicated to addressing digitalisation challenges thoughtfully, exploring strategies, and striving for efficient and cost-effective implementations. Our customer eNPS score is 94/100 and the score shows our dedication to customer satisfaction and achieving customer goals. If you would like to discuss how we could help with your digitalisation challenges, get in touch with us today at sales@weare.fi. Also, learn more about our service here. https://www.weare.fi/en/services/